- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Selecting the right hydraulic cylinder for your log splitter means matching its size and power to the logs you want to split. When choosing a hydraulic cylinder for log splitter use, you must consider the size and hardness of your wood. A log splitter works best when the hydraulic cylinder for log splitter applications fits your specific needs.

Bigger and harder logs require more force from the hydraulic cylinder for log splitter operation.

A larger bore hydraulic cylinder for log splitter use can handle tough wood but demands a strong hydraulic pump.

The right balance between pump flow and pressure ensures splitting is fast and powerful.

A well-matched hydraulic cylinder for log splitter systems lasts longer and performs better than electric log splitters on big or hard logs.

By focusing on these factors, selecting the right hydraulic cylinder for your log splitter becomes straightforward.

Pick a hydraulic cylinder that fits your log size and wood type. This helps you get the right force and speed.

Look at important cylinder parts. Bore size gives more power. Stroke length should match your log length. Rod diameter makes it stronger. Mounting style helps it fit right.

Make sure your cylinder works with your hydraulic pump’s flow and pressure. This keeps splitting safe, quick, and strong.

Use good materials and take care of your cylinder often. This helps your log splitter last longer and stay safe.

Always measure well and follow safety rules. This stops damage and makes splitting logs smooth and easy.

When you choose a hydraulic cylinder for log splitter use, you need to focus on four main features: bore size, stroke length, rod diameter, and mounting style. Each part plays a key role in how well your log splitter works. Understanding these features helps you match the cylinder to your needs and get the best results from your machine.

Bore size is the inside diameter of the cylinder barrel. This measurement controls how much force your hydraulic cylinder for log splitter can create. A larger bore means more power, but it also means the cylinder moves slower because it needs more hydraulic fluid.

Bore Size (in) | Pressure (psi) | Force (tons) | Cycle Time at 11 GPM (sec) | Cycle Time at 16 GPM (sec) |

|---|---|---|---|---|

4 | 3500 | 22 | 14.25 | 9.81 |

4.5 | 2500 | 17 | - | - |

5 | 3500 | 34 | 22.27 | 15.32 |

Most log splitters use bore sizes between 4 and 5 inches. A 4-inch bore works well for small logs. If you split medium to large logs, a 4.5-inch or 5-inch bore gives you more force. For example, a 4.5-inch bore at 2000 PSI can create about 14 tons of force, which is enough for most heavy-duty jobs. Remember, a bigger bore increases force but slows down the cycle time.

Tip: If you want to split large or tough logs, pick a hydraulic cylinder for log splitter with a bigger bore. If you want faster splitting, use a smaller bore, but only for smaller logs.

Stroke length is how far the rod moves in and out of the cylinder. This measurement decides how long a log you can split in one motion. Most log splitters use stroke lengths between 24 and 30 inches, often in 2-inch steps. These sizes match the typical log lengths you find in firewood.

To measure stroke length, first measure the distance between the mounting pin centers when the cylinder is fully retracted. Next, measure the same distance when the cylinder is fully extended. Subtract the retracted length from the extended length to get the stroke.

Note: Always match the stroke length to your log size. If the stroke is too short, you cannot split the whole log. If it is too long, you may damage the basic parts of a log splitter.

Rod diameter is the thickness of the steel rod that moves in and out of the cylinder. Most hydraulic cylinders for log splitter use rods between 1.75 and 2 inches thick. A thicker rod does not increase splitting force, but it does make the cylinder stronger and helps it retract faster. This is because a larger rod reduces the amount of hydraulic fluid needed on the return stroke.

Larger rod diameters make the cylinder retract faster, improving cycle time.

Thicker rods add strength and reduce bending.

Bigger rods cost more, but they last longer under heavy use.

To measure rod diameter, use a caliper to check the outer diameter of the rod.

Mounting style is how you attach the hydraulic cylinder to your log splitter. You need at least two points of contact. The most common mounting styles include:

Clevis End: U-shaped connector with a pin. Allows pivoting and is common in log splitters.

Cross Tube End: Tube welded across the cylinder for a pin or bolt. Offers strong support.

Spherical Bearing (Rod Eye): Ball joint for more movement and less stress.

Threaded Rod End: Lets you adjust length and fit different machines.

Flange Mount End: Flat plate with bolt holes for secure mounting.

Tang End: Single tab with a hole for a pin, good for tight spaces.

Lug Mount: Welded lugs for bolts or pins, strong and stable.

Eye Bracket End: Solid loop for a pin, used in heavy-duty jobs.

Swivel Mount: Allows rotation, useful for changing angles.

Maintenance Tip: Always check and replace worn pins when you change the cylinder. Grease mounts if needed to keep them working smoothly.

When you select a hydraulic cylinder for log splitter replacement, always measure the bore diameter, rod diameter, stroke, retracted, and extended lengths. Use a caliper for bore and rod measurements. Use a tape measure for retracted and extended lengths. Make sure the mounting style matches your log splitter. If you need to make small changes, you can sometimes adjust the mounting or fittings, but never change the stroke length or mounting points too much.

By understanding these features, you can choose the right hydraulic cylinder for your log splitter. This ensures you get the right size, power, and speed for your wood splitting needs.

You need to make sure your hydraulic cylinder matches the pump flow and pressure. The flow rate is measured in gallons per minute, or GPM. This tells you how much hydraulic fluid moves each minute. The flow rate controls how fast your log splitter works. Pressure is measured in pounds per square inch, or PSI. Pressure shows how much force the hydraulic system can make. This force is called tonnage. Tonnage means how much force your log splitter uses to split wood.

Parameter | Role in Log Splitter Operation | Effect on Tonnage Output and Cycle Time |

|---|---|---|

Flow Rate (GPM) | Determines the volume of hydraulic fluid moved per minute | Increases cycle speed (reduces cycle time), does not increase force (tonnage) |

Pressure (PSI) | Determines hydraulic system pressure applied to the log | Directly controls the splitting force (tonnage output) |

Two-Stage Pumps | Switch between high flow/low pressure and low flow/high pressure | Optimize speed and force by adjusting flow and pressure dynamically |

You want a log splitter hydraulic circuit with enough tonnage to split your wood. Higher pressure gives you more tonnage, but it can slow down the speed. A higher flow rate makes the log splitter faster, but it does not add more tonnage. Two-stage pumps help by switching between high flow for speed and high pressure for force. This keeps your log splitter working fast and strong.

If you rev the engine, the cycle time gets faster because more fluid moves. This increases GPM. It does not change tonnage. Tonnage depends on PSI, which does not change with engine speed.

You need to check the valve and port sizes in your log splitter hydraulic circuit. Most log splitters use standard port sizes like 1/2" NPT for work ports and 3/4" NPT for in/out ports. These sizes make it easy to connect hoses and fittings. If your log splitter has different port sizes or threads, you can use adapters to connect them.

Feature | Specification | Impact on Compatibility |

|---|---|---|

Work Port Size | 1/2" NPT | Standard size for hydraulic cylinders, enabling easy connection and replacement without adapters |

In/Out Port Size | 3/4" NPT | Ensures compatibility with hoses and fittings used in various log splitters |

Maximum Pressure | 3500 PSI | Supports high load bearing, ensuring reliable operation |

Valve Design | Auto Control Detent Valve | Facilitates use across different log splitters due to standard port sizes and robust construction |

SAE O-Ring Boss fittings use straight threads and an O-ring to seal tight.

These fittings help stop leaks and make connections simple.

You can use adjustable or non-adjustable types for different needs.

JIC fittings also work well with many hydraulic systems.

Adapters let you connect different port sizes or thread types. This helps you build a strong log splitter hydraulic circuit. It will handle high pressure and give you the right tonnage for your job.

Choosing the right hydraulic cylinder for your log splitter depends on both log size and hardness. These two factors decide how much force you need to split wood. If you try to split a large or hard log with a weak cylinder, your log splitter will struggle or even break. When you match the cylinder to the log size and hardness, you get better results and protect your equipment.

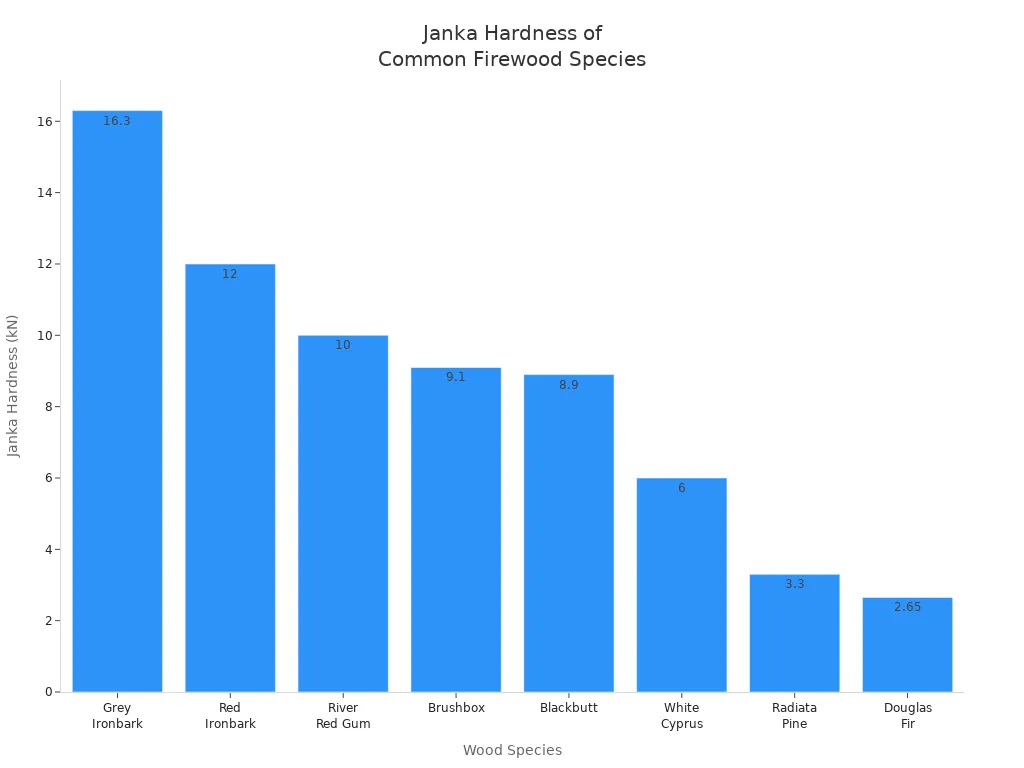

Different wood types have different hardness levels. Hardwoods like ironbark and red gum are much tougher than softwoods like pine or fir. The Janka scale measures wood hardness. Higher numbers mean harder wood, which needs more force from your log splitter.

Wood Species | Janka Hardness (N) | Wood Type |

|---|---|---|

Grey Ironbark | 16.3 | Hardwood |

Red Ironbark | 12 | Hardwood |

River Red Gum | 10 | Hardwood |

Brushbox | 9.1 | Hardwood |

Blackbutt | 8.9 | Hardwood |

White Cyprus | 6 | Softwood |

Radiata Pine | 3.3 | Softwood |

Douglas Fir | 2.3 - 3 | Softwood |

Tip: If you often split hardwoods, pick a log splitter with a larger bore cylinder to get more force. For softwoods, a smaller cylinder works well and gives faster cycle times.

You will find that log size also affects your choice. Most residential users split logs under 20 inches in diameter, while commercial users may handle logs up to 36 inches or more. The length of the log also matters, but diameter and hardness have the biggest impact on the force needed.

Log Diameter Range (inches) | User Type | Common Wood Types | Recommended Splitter Force (tons) | Example Product(s) |

|---|---|---|---|---|

Under 20 | Residential | Softwoods (pine, birch) | 25-30 | Blue Diamond 25 Ton Log Splitter |

20 to 36 | Commercial | Hardwoods (oak, hickory, ash) | 30-35 | Top Dog 36" Log Splitter |

Over 36 | Commercial/Heavy Duty | Dense hardwoods | Over 35 | TM Warrior Skid Steer Log Splitter |

For 6-inch logs, a 4 to 10 ton log splitter is enough.

For 12-inch logs, you need 12 to 22 tons.

For 20-inch logs, use 20 to 26 tons.

For 24-inch logs, pick 27 to 30 tons.

When you select a hydraulic cylinder, always check the log size and hardness you plan to split. This helps you choose the right force and cylinder size for your log splitter. You will get smoother operation and longer equipment life.

When you start choosing the right log splitter cylinder, you need to look at your log splitting requirements. Each cylinder part affects how your log splitter works. You want to match the cylinder to your needs for the best performance and efficiency.

Decide on Bore Size

Think about how often you use your log splitter and the size of your logs. For home use, a 4-inch bore works well. For heavy-duty or commercial jobs, pick a 5 or 6-inch bore. The bore size controls the force, or tonnage, your cylinder can create.

Pick the Stroke Length

Measure your logs. For most logs, a stroke length between 16 and 24 inches fits. Longer strokes help with bigger logs but may slow down the cycle.

Choose Cylinder Type

Single-acting cylinders cost less and work for simple jobs. Double-acting cylinders give you faster, more efficient splitting.

Select Rod Diameter

A larger rod makes the cylinder retract faster and last longer. This helps with efficiency and performance.

Match Hydraulic System

Make sure your pump, hoses, and valves can handle the cylinder’s bore and stroke. The hydraulic pressure and flow must fit your cylinder for safe and smooth operation.

Pick the Right Mounting Style

Check your log splitter’s design. Use clevis, trunnion, or flange mounts as needed.

Tip: Always check the pressure rating of your cylinder. Never exceed the maximum pressure to keep your log splitter safe.

You need to balance splitting force and speed for top performance. A larger cylinder bore gives you more tonnage, but it slows down the cycle because it needs more hydraulic fluid. Smaller cylinders move faster but create less force. If you want both speed and power, use a two-stage pump or a regeneration valve. These features boost efficiency and keep your log splitter working at its best.

Larger cylinders = more force, slower speed.

Smaller cylinders = less force, faster speed.

Upgrading pumps and hoses can help, but it adds cost and complexity.

You get the best efficiency and performance by matching cylinder size, hydraulic pressure, and log size. Always choose a cylinder that fits your log splitting requirements for safe and reliable operation.

You want your log splitter to last a long time. The cylinder needs strong materials and special coatings for hard work. Many makers use hard chrome plating on the rod. This coating helps the rod slide easily and keeps it from rusting. It also protects against scratches and damage. Some cylinders use laser cladding or thermal spray coatings. These add tough layers to the rod for more strength in rough places.

Hard chrome plating stops rust and wear on the rod.

Laser cladding gives an extra strong layer for longer life.

Thermal spray coatings use metal or ceramic to stop scratches and rust.

A smooth rod that resists rust keeps seals safe and lowers friction. This helps your log splitter last longer and work better. In wet or outdoor places, thicker coatings or nickel-chrome plating make the cylinder even stronger. Special coatings also help the cylinder work well under high pressure and heavy loads.

Taking care of your log splitter helps it work its best. Always use the right cylinder for your machine. Clean hydraulic fluid is very important. Change filters often to keep out dirt and junk. Check the cylinder rod for bends or scratches. Look for leaks around seals and hoses. Fix leaks fast so they do not get worse.

Check the cylinder barrel for swelling or cracks.

Do not sideload, or the rod can bend and move wrong.

Watch for leaks, dirty fluid, or rust.

Keep spare parts and know where to get repairs.

Quick checks and small repairs help you avoid problems and keep your log splitter strong. Good care also keeps the cylinder safe from damage by high pressure or heat.

Safety is important every time you use your log splitter. If the cylinder fails, it can leak, break, or hurt someone. Bent rods, old seals, and dirty fluid are common dangers. Too much pressure can break the cylinder or blow out seals. If the cylinder is not lined up right, it wears out faster and can break suddenly.

Always use a good cylinder made for your log splitter.

Make sure the rod size and finish fit the job.

Keep hydraulic fluid clean and change it when needed.

Never go over the pressure limit for your cylinder.

Protect the cylinder from bad weather and chemicals.

Install the cylinder right to stop sideloading.

Check seals, bushings, and mounts often for wear.

If you follow these steps, your log splitter will last longer and work better. You will also be safer and have fewer problems with your equipment.

Choosing the right log splitter cylinder starts with knowing your needs. You should match the cylinder specs to your log splitter, log size, and wood type. Always check if your log splitter can handle the cylinder and fits your hydraulic system. Use a checklist to compare bore size, stroke length, and rod diameter. If you want more power than an electric log splitter, pick a strong cylinder. Ask a professional if you feel unsure. The right log splitter makes splitting wood safe and easy.

You should match the cylinder size to your log size and wood type. For most home use, a 4-inch bore works well. For bigger or harder logs, use a 5-inch bore. Always check your log splitter’s manual for the best fit.

First, measure the bore diameter and rod diameter with a caliper. Next, measure the stroke by checking the distance the rod travels. Finally, record the retracted and extended lengths. Write down the mounting style. Use these numbers to find a matching cylinder.

No, you cannot use just any cylinder. You must match the bore, stroke, rod size, and mounting style. The cylinder must handle your pump’s pressure and flow. Using the wrong cylinder can damage your log splitter or cause safety problems.

You should check your cylinder before each use. Look for leaks, rust, or bent rods. Clean the rod and check the fluid level. Replace worn seals or pins right away. Regular checks help your log splitter last longer and work safely.

A cylinder that is too big will split wood slowly and may overload your pump. A cylinder that is too small will not have enough force for tough logs. Always choose a cylinder that matches your log size and your hydraulic system.