- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2025-08-26 Origin: Site

What is most important when choosing hydraulic cylinders for log splitters? The right cylinder helps you split wood safely and easily. It also makes sure your log splitter works well every time. Have you ever tried to split a hard log and saw the cylinder having trouble? Using the wrong cylinder can make the machine slow or break. It can even cause dangerous problems like the cylinder rod coming apart. The U.S. Consumer Product Safety Commission says many log splitter injuries happen because of the wrong equipment. Always pick hydraulic cylinders for log splitters that fit the size and kind of wood you use. Before you look at details, think about what you need from your log splitter.

Pick a hydraulic cylinder with the right bore size. This should match the wood you split. This helps you work safely and easily.

Choose a stroke length a bit longer than your longest logs. This stops wasted energy and missed splits.

Make sure the cylinder’s pressure rating fits your hydraulic pump. The port size should also match. This keeps things smooth, fast, and safe.

Get a cylinder with a thick rod for more strength. This helps it last longer. It is important if you split big or hard logs.

Check your cylinder often for leaks. Keep fluid levels correct. Use good parts. This helps your log splitter work well.

When you choose a hydraulic cylinder for your log splitter, you need to think about the force it can deliver. Industry experts say the most important factor is the required force or pressure capacity, also called tonnage. This force must match the type of wood you want to split. Hardwoods like oak or hickory need more force than softwoods. If you try to split green logs, you will need even more power because they are tougher than seasoned wood. The size of the log matters too. Thicker logs require a cylinder with higher tonnage.

You should also look at the bore diameter and stroke length of the cylinder. These two features decide how much force the cylinder can create and how far it can push the log. Most log splitters need cylinders that can handle high working pressures, often up to 3000 PSI or more. If you pick a cylinder with the right specs, your log splitter will work smoothly and split logs quickly.

Tip: Always check the cylinder’s pressure rating and make sure it matches your pump. This helps you get the best performance from your log splitter.

Using the right hydraulic cylinder keeps you safe and makes your work easier. If the cylinder cannot handle the force needed, it may fail or break. This can cause accidents or damage your log splitter. A cylinder that matches your needs will split logs without straining the machine. You will spend less time fixing problems and more time splitting wood.

A good match between the cylinder and your log splitter also means you use less energy. The machine will not have to work harder than it should. This saves you money on repairs and keeps your log splitter running longer.

The bore size of a hydraulic cylinder is one of the most important features you need to consider. Bore size means the inside diameter of the cylinder. This measurement decides how much splitting force your log splitter can create. A larger bore gives you more power, which helps you split bigger and tougher logs. You can use this table to compare common bore sizes and their uses:

Bore Size (inches) | Force at 2500 psi (tons) | Force at 3000 psi (tons) | Application / Notes |

|---|---|---|---|

3.0 | ~9 | ~10 | Good for small logs and fast cycles |

4.0 | 15 - 19 | 19 | Best for most users; splits logs 8-24 inches wide |

5.0 | ~27 | ~30 | Needed for large logs; slower operation |

A 4-inch bore is the most common choice for hydraulic cylinders for log splitters. It gives you a good balance between splitting force and speed. If you often split large hardwood logs, you may need a 5-inch bore. This size can handle logs that smaller cylinders cannot split.

Tip: Always match the bore size to the size and type of wood you plan to split. Too small, and you will not get enough force. Too large, and you may slow down your work.

Bore size does not only affect power. It also changes how fast your log splitter works. Larger bore cylinders need more oil to move the piston. This means the cycle time, or how long it takes to split a log and return, will be slower if your pump stays the same. Smaller bore cylinders use less oil, so they move faster but give less splitting force.

If you want faster cycles, choose a smaller bore or increase your pump’s flow rate.

Larger bore cylinders give more power but slow down the cycle unless you upgrade your pump.

Rod diameter also matters. A thicker rod can help the cylinder retract faster.

You need to find the right balance. Think about how much splitting force you need and how quickly you want to work. The right hydraulic cylinder will help you split logs safely and efficiently.

Stroke length tells you how far the piston inside your hydraulic cylinder can move. This distance decides the maximum length of log you can split in one cycle. If you choose a stroke that is too short, you will not split the whole log. If you pick a stroke that is too long, you may waste time and energy.

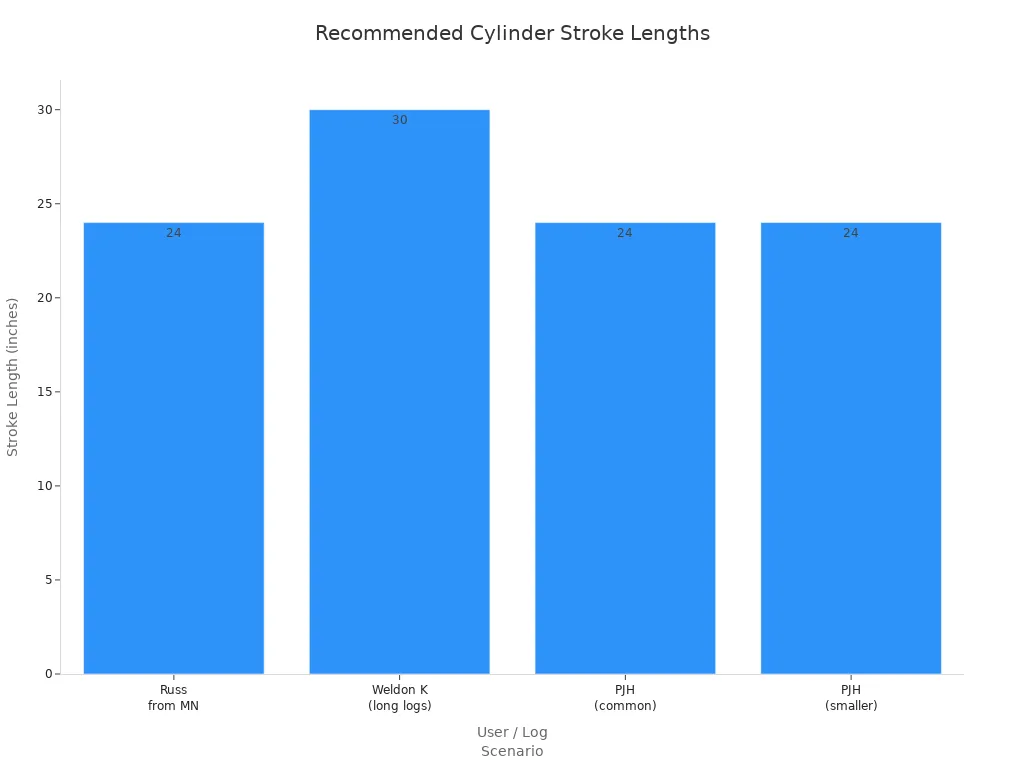

Most users find that a stroke between 20 and 30 inches works best for log splitters. A stroke just longer than your typical log length gives you the best results. For example, a 24-inch stroke fits most firewood logs. If you often split longer logs, a 30-inch stroke may suit you better.

User | Cylinder Size (Diameter x Stroke) | Log Size / Notes |

|---|---|---|

Russ from MN | 3.5" x 24" | Smaller diameter for speed; splits well at 2500 psi; rarely fails |

John Deere D | 4.5" diameter (stroke not given) | Splits 12-14" diameter, 10-12" long logs |

Jeff NWOH | 6" diameter (stroke not given) | Runs on 10hp pump; can cut through tough logs |

Weldon K | 4" x 30" | Handles logs up to 30" length; 24" stroke typical for smaller logs |

PJH | 4" x 24" and 3" x 24" | 24" stroke common; performance varies with tractor hydraulic power |

Tip: Always measure your logs before choosing a stroke length. Pick a stroke that is just a bit longer than your longest log.

Rod diameter is another key part of your hydraulic cylinder. A thicker rod gives you more strength and helps the cylinder last longer. When you split logs, side loads can push against the rod. If the rod is too thin, it may bend or wear out faster.

A larger rod diameter helps in several ways:

It resists bending when logs push sideways.

It reduces stress on seals and bearings, so your cylinder lasts longer.

It makes the cylinder retract faster because it needs less oil on the return stroke.

If you want your log splitter to work for many years, choose a cylinder with a strong, thick rod. This choice keeps your machine safe and helps you split wood without trouble.

You need to know the pressure ratings when you look at log splitter hydraulics. Most log splitters use hydraulic systems with standard PSI ratings between 2000 and 2250 PSI. Many systems have relief valves set around 2250 PSI. Some hydraulic pumps can reach up to 3000 PSI for continuous use, but running at this high pressure all the time is not safe or good for your equipment. The relief valve controls the highest pressure your system can reach. This setting decides the maximum force your log splitter can make.

Cylinders come with their own pressure ratings, often 2500 PSI or 3000 PSI. You should always pick a cylinder with a working pressure rating that matches or is higher than your system’s relief valve setting. If you use a cylinder with a lower rating, it can fail early and may cause safety problems. Choosing a cylinder with a higher rating gives you a safety margin, but you may need to adjust your setup.

Note: Force output depends on pressure. Lowering the relief valve setting will reduce the force, but for most jobs, you will not notice much difference in performance.

Your hydraulic pump must match your cylinder for the best results. Log splitter cylinders often work at pressures up to 3500 PSI. They usually have bore sizes between 4 and 5 inches and strokes from 24 to 30 inches. The hydraulic pump must have the right pressure rating, flow rate, and port size to work with these cylinders. If the pump cannot supply enough flow, your log splitter will run slowly. If the pump’s pressure is too low, you will not get enough splitting force.

Here is a table to help you see how pump and cylinder specs line up:

Specification Aspect | Hydraulic Pump (19 GPM 2-Stage) | Log Splitter Cylinder (35 Ton, 5" Bore) |

|---|---|---|

Flow Rate | 19 GPM @ 3600 RPM | Depends on pump flow |

Maximum Pressure | 4000 PSI | 3500 PSI |

Port Sizes | Inlet: 1"; Outlet: 1/2" | 1/2" NPT |

Mounting | Bolt circle 2.83 in; 4 holes | 1-1/8" clevis holes |

Valve Compatibility | Up to 3500 PSI | Valves rated for 3500 PSI |

You should always check that your hydraulic pump and cylinder have matching specs. This ensures your log splitter hydraulics work safely and efficiently. When you match the working pressure and flow rate, you get the right force and speed for splitting logs.

When you look at a log splitter hydraulic circuit, you will find different cylinder types. Each type has its own strengths and weaknesses. You should know how these types work so you can pick the best one for your needs. Here is a table to help you compare the main cylinder types:

Hydraulic Cylinder Type | Advantages | Disadvantages |

|---|---|---|

Single Acting | Simple design, low cost, easy to install | Less force, spring can wear out, inconsistent strokes |

Double Acting | Strong push and pull, better control, faster cycles | Higher cost, larger size, more complex |

Ram | Cheap, works for both vertical and horizontal splitting | Needs guides for horizontal use, no piston |

Telescopic | Saves space, long reach, can be single or double acting | Complex design, more parts to maintain |

Tie Rod | Easy to repair, strong, used in many machines | Bulky, takes up more space |

Welded | Compact, long life, good for outdoor use | Hard to repair, needs special tools |

You should choose a cylinder type that matches your log splitter hydraulic circuit and the kind of wood you split. Double acting cylinders give you more control and speed, while single acting cylinders cost less and are easier to set up.

Port size is another key part of your log splitter hydraulic circuit. The port is the opening where oil flows in and out of the cylinder. The size of this port affects how fast oil moves and how quickly your cylinder works.

Larger ports let more oil flow. This means your cylinder moves faster and your log splitter works more efficiently.

Smaller ports slow down the oil. This can make your cylinder move slowly and cause the oil to heat up.

If you use a big pump with small ports, your system can run hot and lose efficiency. For example, using 1/2 inch ports with a 22 GPM pump can make the oil too hot. You should match the port size to your pump’s flow rate. This helps your hydraulic cylinders for log splitters work at their best.

Factor | Effect on Flow Rate | Effect on Cylinder Speed | Impact on Efficiency |

|---|---|---|---|

Larger Ports | Higher flow, less restriction | Faster movement | Less heat, better efficiency |

Smaller Ports | Lower flow, more restriction | Slower movement | More heat, lower efficiency |

Tip: Always check the port size when you choose a cylinder. The right port size keeps your log splitter hydraulic circuit running smoothly and safely.

When picking a hydraulic cylinder for your log splitter, you should think about how it is made. There are two main types: welded and tie-rod cylinders. Each type has its own good points that affect how long the cylinder will last and how easy it is to fix.

Welded cylinders have one cap and the mounts are welded right onto the barrel. This makes them very strong and good for hard jobs. Welded cylinders can handle rough places and usually last longer than tie-rod cylinders. But if you need to fix a welded cylinder, you will need special tools and skills.

Tie-rod cylinders use steel rods to hold the ends in place. You can take them apart with normal tools, so fixing and taking care of them is easier. Tie-rod cylinders are bigger and need more room, but they cost less and are simple to fix. For log splitters, tie-rod cylinders are a smart pick if you want easy repairs.

Tip: Look at your cylinder often to check for leaks or damage. Oil the moving parts and change old seals to keep your log splitter working well.

The materials inside your hydraulic cylinder help it last a long time. High-strength steel gives the cylinder power and makes it tough. Special coatings like chrome plating stop rust and wear.

Wear rings, also called guide rings, are inside the cylinder. They are made from strong but soft stuff like fiberglass. These rings keep metal parts from rubbing together, which protects the inside and helps it last longer. Seals made from nitrile rubber, polyurethane, or Teflon keep oil inside and stop leaks.

Here is a table that shows how different parts and materials help your cylinder last longer:

Component | Material/Feature | Benefit |

|---|---|---|

Rod | Chrome-plated, hardened steel | Fights rust and wear |

Piston and Gland | Premium-grade steel | Makes it strong and last longer |

Wear Rings | Fiberglass or similar fibrous material | Stops metal parts from touching |

Seals | Nitrile, polyurethane, or Teflon | Stops leaks and keeps pressure steady |

Cylinder Barrel | Honed cold-drawn tubing | Runs smooth and wears out less |

If you pick a cylinder with these features, your log splitter will work well and last for many years, even if you use it in tough places.

When you need to replace a hydraulic cylinder on your log splitter, accurate measurement is key. If you measure wrong, the new cylinder may not fit or work as expected. You can follow these steps to get the right measurements:

Measure the stroke length. Start by measuring from the center of one pin to the center of the other pin when the rod is fully retracted. Then, do the same when the rod is fully extended. The difference between these two numbers is your stroke length.

Check the bore diameter. Use a caliper or bore gauge to measure the inside diameter of the cylinder barrel. If you do not have a bore gauge, measure the outside diameter and subtract the wall thickness.

Measure the rod diameter. Use a caliper for the most accurate result.

Record mount dimensions. Look at the type of mount (clevis, cross tube, pin eye, trunnion, or flange). Measure the length, gap, and pin diameter.

Note port orientation and size. Ports can sit at different positions, such as 12, 3, or 9 o’clock. Measure the thread size, which is often 1/4, 3/8, 1/2, or 3/4 inches.

Drain hydraulic fluid before you start. This prevents spills and helps you move the rod smoothly.

Check pin sizes and bushings. Sometimes, you need to replace these parts too.

Be careful with stroke length. A longer stroke than the original can damage your machine.

Use the right tools. A tape measure and calipers work best. A bore gauge gives extra accuracy.

Tip: Minor adjustments, like shimming or using reducer fittings, can help if your new cylinder is not an exact match.

Many people make simple mistakes when replacing hydraulic cylinders. You can avoid these problems by watching out for the following:

Not measuring pin centers at both full retraction and extension. This can lead to buying a cylinder that does not fit.

Choosing a larger bore without matching the rod size. This slows down your cycle time.

Upsizing the cylinder when your current one works well. Bigger is not always better and can make your splitter slower.

Using dual cylinders that do not match in length or hose size. This can cause bending or binding.

Ignoring hose and port compatibility. Mismatched hoses and ports can lower performance.

Note: For most log splitters, a single, well-matched cylinder works better than two smaller ones. Always double-check your measurements before you buy a replacement.

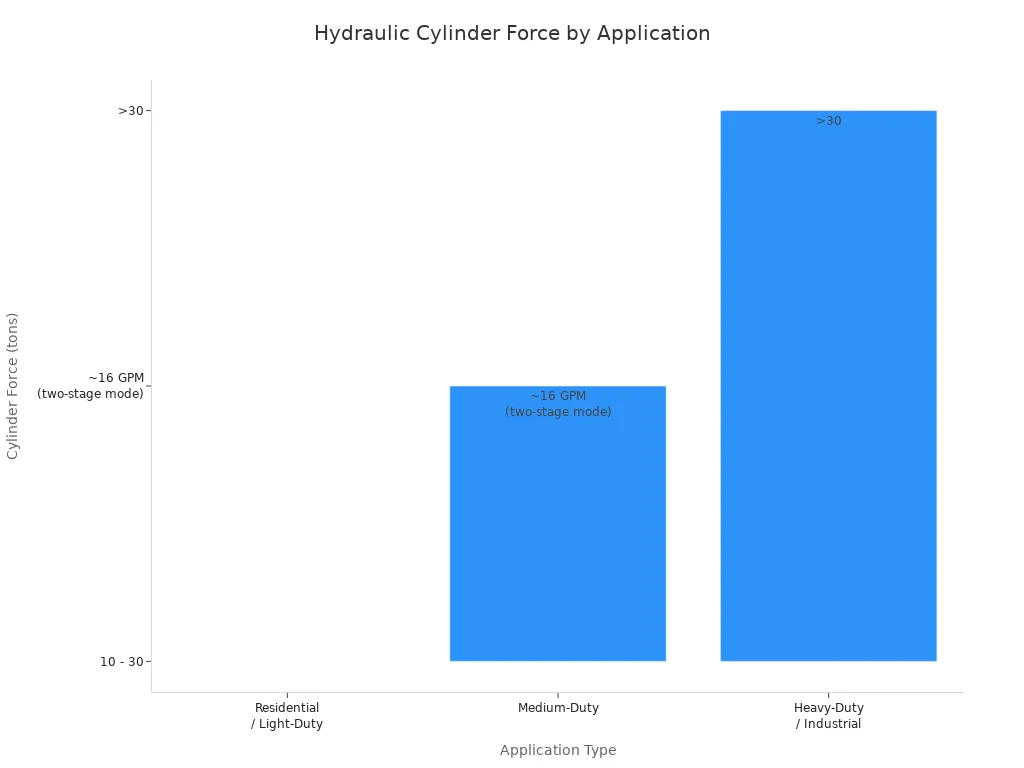

You want your log splitter to work well and be safe. To do this, you need to pick a cylinder that fits what you need. Think about how often you split wood and what kind of logs you have. If you only split firewood at home, you do not need the biggest cylinder. If you split big or hard logs for work, you need a stronger one.

Here is a table to help you see what to look for:

Criterion | Specification / Recommendation | Usage Context / Notes |

|---|---|---|

Bore Size | 4-inch bore | Good for home use or splitting firewood sometimes |

5-inch or 6-inch bore | Better for splitting often or bigger logs | |

6-inch bore | Best for heavy jobs or very large, tough logs | |

Stroke Length | 12 to 16 inches | Fine for people who split normal-sized logs |

16 to 24 inches | Good for those who split bigger logs often | |

24 inches or more | Best for big log splitters used for hard work | |

Pressure Rating | Match cylinder rating to highest pressure your system uses | Do not use a cylinder with a lower rating than your machine needs |

Rod Diameter | Bigger rod makes the cylinder stronger and faster | This helps the cylinder last longer and work better |

Port Size | Bigger ports (like 3/4 inch) let oil move faster | Small ports (like 1/2 inch) slow things down |

Cylinder Type | Double-acting cylinders work best for fast splitting | Single-acting can be okay for simple or cheaper machines |

Compatibility | Make sure the cylinder works with your valves and pump | The valve should handle as much flow as your pump gives |

Think about how you will use your log splitter. People who use it at home need less power and a smaller pump. People who use it for work need more power, faster oil flow, and stronger cylinders. The chart below shows how much force and pump flow you need for different jobs:

Remember these things:

Bigger bore cylinders need more oil and move slower unless you get a better pump.

Rod diameter changes how fast the cylinder comes back and how strong it is.

Always match the cylinder’s pressure rating to your machine’s highest pressure.

Use valves and pumps that can handle the flow your cylinder needs.

Bigger ports help your log splitter work faster and stay cooler.

If you want your log splitter to last, make sure all the parts work well together. For example, timberwolf log splitters use strong beams and good cylinders for hard jobs. You can look for these features in other brands too.

You want a cylinder that does not cost too much but still lasts a long time. Price and quality usually go together. Some brands, like RuggedMade, make hydraulic cylinders for log splitters with strong steel barrels, chrome-plated rods, and tough seals. These things help the cylinder handle high pressure and last longer. RuggedMade cylinders also have welded mounts and threaded end caps, so they are easy to fix.

Other good brands are:

Brave: Not expensive and works well for most people.

Iron and Oak: Used in rental shops, known for being strong.

Oregon: A trusted brand for a long time.

Boss Industrial: Has special hydraulic systems with unique gear sets.

When you pick a cylinder, think about how easy it is to take care of. Here are some tips to help you:

Pick a cylinder with the right tonnage for your wood. Too much force can break your machine and is not always needed.

Check what people say about the brand and read reviews.

Make sure you can get new parts if you need them.

Look for a good warranty and helpful customer service.

Do not pick a cylinder that works too fast if you want it to last.

Tip: Take care of your log splitter by checking for leaks, keeping the fluid full, and using real replacement parts.

If you follow these steps, you will find a cylinder that fits your needs and your budget. You will also be able to split wood safely and easily for a long time.

Choosing the right hydraulic cylinder for your log splitter helps you work safer and faster. Focus on your needs, not just the biggest or most powerful option. Each cylinder feature changes how your machine works:

A larger bore gives more force but slows down the cycle.

A smaller bore speeds up splitting but lowers force.

A thicker rod helps the cylinder retract faster.

Higher PSI increases force, while higher GPM boosts speed.

Quick Checklist:

Match bore size to your log size.

Pick the right stroke length.

Check rod diameter and port size.

Make sure the cylinder fits your pump and valve.

Understanding these features lets you get the best performance and efficiency from your log splitter.

You should match the cylinder size to your log size. For most home use, a 4-inch bore works well. If you split large or tough logs, choose a 5-inch bore. Always check your log length and wood type before buying.

Measure the stroke length from pin to pin when the rod is fully retracted and extended. Check the bore diameter inside the barrel and the rod diameter. Write down the port size and mounting type. Accurate measurements help you find the right fit.

No, you cannot use just any cylinder. The cylinder must match your pump’s pressure and flow. The bore, stroke, and port size should fit your splitter. Using the wrong cylinder can cause slow cycles, low force, or even damage.

Check your cylinder before each use. Look for leaks, worn seals, or bent rods. Keep the rod clean and the fluid at the right level. Regular checks help your cylinder last longer and keep your splitter safe.

Type | Pros | Cons |

|---|---|---|

Welded | Strong, compact, durable | Harder to repair |

Tie-Rod | Easy to repair, less costly | Bulkier, less tough |

Tip: Pick welded cylinders for heavy use. Choose tie-rod cylinders if you want easy repairs.